- TOP

- Business activities

- Environmental Resources Development Division

- Solar Engineering

- Home Sanitation

- Establishment Sanitation

- Environmental Resources Development

- Energy Business

Environmental Resources Development Division (ERD)

As the leading company of the Venous Industry*, SANIX has been trying to balance between environmental concerns with economic growth.

* Venous Industry: made-up word to call the industry recycling the wastes.

While the request for environmental protection has been growing around the globe, the volume of industrial wastes has been expanding day by day. The capacity of the landfills is so limited that the wastes are so required to be reduced, recycled and reused. ERD has been contributing to build the circulating society, by recycling waste liquid, and by utilizing waste plastics as a fuel.

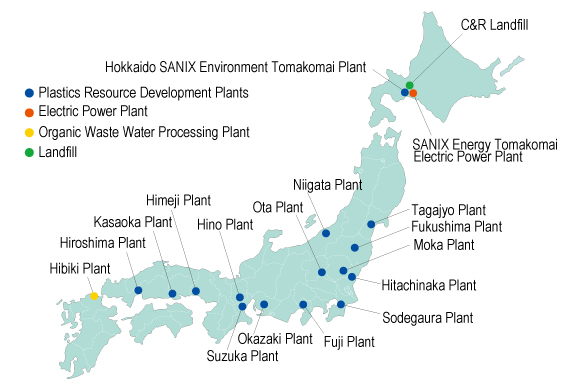

Convert waste plastics into fuel

The waste plastic processing business operate 15 plants nation wide reusing waste plastics by using them as fuel. As an alternative energy to coal and petroleum energy resources, SANIX is the only company in the world that has developed plastic waste thermal recycling plants on a very large scale.

Plastics Resources Development Plant

Treated waste plastics in wrap

Final Disposal Plant(C&R Inc.)

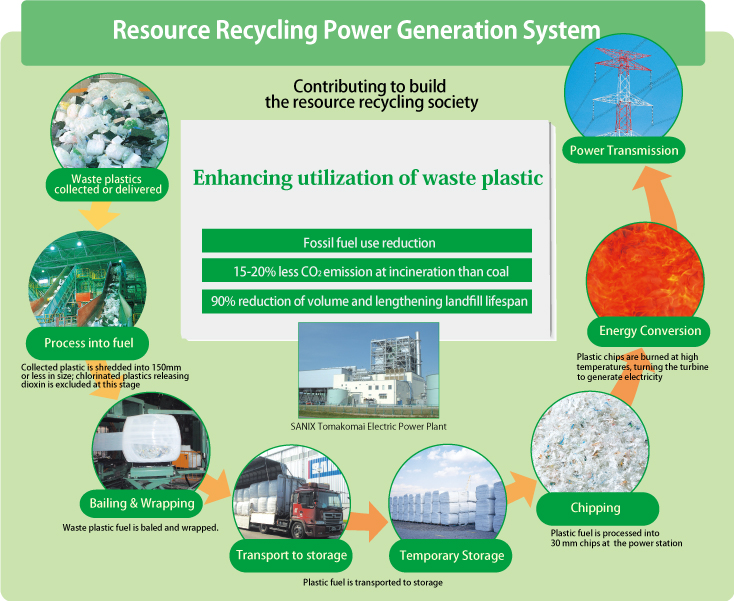

Resource Recycling-based power generation system

Incineration of the waste plastics, compared with coal, brings higher calorific value as well as less emission of CO2 and ashes. Our electric power plant in Tomakomai, Hokkaido, uses only this unique fuel to realize the environmentally friendly power generation.

SANIX Energy Electric Power Plant (Tomakomai, Hokkaido)

Commercial & industrial organic waste liquid purification

In the safeguard closed system, our Hibiki Plant,

the largest organic liquid processing plant in Japan, eliminates 99% of contaminants from the waste liquid and recycles it into usable resources.

With a large-scale processing capability and own berth for vessel transportation, our Hibiki Plant quickly purifies large scale of waste liquid from such as food-service and food-processing companies.

Moreover, the dehydrated reclaimed materials are being recycled into such as composts and cement mixtures.

Besides, our bio-methane-gas power generation system is expected to be put into operation in the near future.

Hibiki Organic Waste Liquid Processing Plant (Kitakyushu, Fukuoka)

*Venous Industry is a term used in Asia to mean industrial recycling, from waste back into raw materials for new production.

Location of ERD Plants and Facilities

Recycling Energy from Waste Plastics(Resource Recycling-Oriented Power Generation Systems)

Industrial Waste Increasing in Accordance with Economic Development.... The disposal of these materials is an important social issue. SANIX entered the industrial waste treatment business in 1994 to meet the needs of the times. In the course of its operation, we focused on the high calories burned by plastics, and developed a resource-recycling power generation system that recycles plastics that had been simply burned and disposed of at landfills as energy. Waste plastics discharged from manufacturing plants and other plants are processed into fuel at 15 plants nationwide and used as fuel for power generation at SANIX Energy Tomakomai Power Station (subsidiary of SANIX, Hokkaido). Recycled as energy.

- Solar Engineering

- Home Sanitation

- Establishment Sanitation

- Environmental Resources Development

- Energy Business